Working With Performance Fabrics

I would like to tackle one of the trickiest substrates to present itself in many years; Performance Moisture Wicking Fabrics. These products come in many different brands, styles, weights and fabric properties but one characteristic that remains constant is these fabrics tend to have a great deal of stretch.

Additionally these fabrics stretch in all directions; this makes for particularly challenging embroidery and success is dependent on quality digitizing for a programmer who knows what they are doing as well as superior embroidery technique.

The technique I will describe takes extra time for garment prep but is proven to work on a production floor with more than 600 embroidery heads embroidering over 4 million garments a year. If you want to save some money on redcuing damaged product and lost productivity give this a try; it is not the only way…but when properly implemented it will work.

The Most important thing to remember is your embroidery backing is used to stabilize and reduce the stretch inherent to performance fabrics. Proper backing with quality digitizing and the spray adhesive technique will allow for superior results.

1. Make sure your digitizer is 100% aware they are programming for performance fabric. This is CRITICAL.

2. Use a high quality 3.5oz or heavier cut-away backing.

3. Obtain KK-100 Fabric Adhesive.

4. Turn your garment inside out.

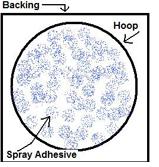

5. Very lightly spray the center portion of your backing with the

KK-100 and then apply the backing to the fabric to the location on the inside of the shirt where the embroidery will go taking care to NOT stretch the material and making sure there are no wrinkles or puckers in the area under the backing. If you get any pooling of adhesive on the backing you have used too much. Discard and create a new piece.

6. Avoid getting adhesive where hoop will press into shirt.

7. Turn shirt right side out and hoop as normal. Make sure 100% of the backing is captured by hoop so there is even fabric tension across the entire hooped location.

8. Under no circumstance should you over tighten the hoop. Never use a wrench or screwdriver to tighten the hoop. Fabric should be taught but not stretched.

9. Embroider as usual on slightly reduced speed.

Thank you so much for directing me to this blog. I’m returning to the shop later tonight and will try this method. When I monogrammed 25 years ago they did not have this type of fabric so I’m very pleased to have you direct me in the right direction.

Thank You

Kathryn

Thanks, Steve for the helpful hints. I had a question about this fabric a few months ago and I wasn’t sure how to handle it. My question, however, is “If you use a heavier cut-away backing, won’t it be too stiff for the fabric?” Is there a particular stabilizer you would suggest? Thanks

Doris

Hi Doris,

There are “heavier” stabilizers that still have soft hands. I personally like a product called AllStitch 2. Because of how this product is made it provides the performance of a heavyweight weight backing but it feels like a lightweight backing.

Steve

Why is it some designs sew out good flat, then you put in hat hoop then it doesn’t sew out right! 1 destroy hat or two.

Steve, thank you. I will look for that stabilizer.

Doris

This is a “big” question I will adress in the March blog post.